Kaip atpažinti ENplus® sertifikuotą įmonę?

Visos ENplus® sertifikuotos įmonės (įskaitant sustabdytus sertifikatus) yra išvardintos mūsų puslapyje, sąrašas yra nuolat atnaujinamas. Įmonės, kurių sąraše nėra, nėra sertifikuotos ENplus®.

ENplus® ST 1001 - ENplus® medienos granulės – Reikalavimai įmonėms

→ Recognition of the technology for small-scale delivery (v.1 March 2023)

ENplus® ST 1002 - Reikalavimai sertifikavimo ir bandymų įstaigoms, atliekančioms ENplus® sertifikavimą

➟ ENplus® ST 1002 – Technical corrigendum 1

➟ ENplus® ST 1002 – Technical corrigendum 2

ENplus® ST 1003 - ENplus® prekės ženklų naudojimas – Reikalavimai

ENplus® PD 2001 - Structure and development of ENplus® documentation

ENplus® PD 2002 - Skundų ir apeliacijų teikimo tvarka

ENplus® PD 2003 - Issuance of permissions for the use of the ENplus® trademarks

ENplus® PD 2004 - ENplus® listing of certification and testing bodies

ENplus® PD 2005 - Governance of the ENplus® certification scheme

ENplus® PD LT 2006 - ENplus® sertifikavimo schemos mokesčiai

ENplus® PD 2007 - Investigation and resolution of fraudulent use of the ENplus® trademarks

ENplus® PD 2008 - Handling confidential and personal information

ENplus® GD 3001 - Storage for wood pellets

ENplus® GD 3002 - ENplus® translations of the pellets bag design

ENplus® GD 3004 - Plausibility checks of mass balance systems

Tai paraiškos forma, skirta medienos granulių gamintojams, norintiems gauti ENplus® sertifikatą.

Jūsų paraiškai užpildyti gali prireikti toliau pateiktų duomenų lapų:

Tai paraiškos forma, skirta medžio granulėmis prekiaujančioms įmonėms, norinčioms gauti ENplus® sertifikatą.

Jūsų paraiškai užpildyti gali prireikti toliau pateiktų duomenų lapų:

Tai paraiškos forma, skirta medžio granulių paslaugų teikėjams, norintiems gauti ENplus® sertifikatą.

Jūsų paraiškai užpildyti gali prireikti toliau pateiktų duomenų lapų:

Visos ENplus® sertifikuotos įmonės (įskaitant sustabdytus sertifikatus) yra išvardintos mūsų puslapyje, sąrašas yra nuolat atnaujinamas. Įmonės, kurių sąraše nėra, nėra sertifikuotos ENplus®.

Visuose sertifikuotos įmonės komunikacijos šaltiniuose (interneto puslapyje, skrajutėje ir t. t.), kur yra nuorodos į ENplus® sertifikuotas granules, turėtų būti galiojantis sertifikavimo ženklas. Komunikacijos šaltiniuose pateikiama, informacija apie sertifikuotą įmonę turėtų sutapti su informacija pateikiama sertifikuotų įmonių sąraše. DAUGIAU INFORMACIJOS

Sertifikato sustabdymas reiškia, kad tam tikrą laiko tarpą, įmonė negali gaminti ar parduoti medžio granulių, naudodama ENplus® prekės ženklą. Patikrinkite sertifikato galiojimą prieš bendradarbiaudami su konkrečia įmone.

ENplus® logotipas ir terminai “ENplus®” ir “ENplus A1″® yra užregistruoti, pagal Madrido susitarimą ir protokolą, tarptautiniame Pasaulio intelektinės nuosavybės organizacijos (PINO) biure, kaip Tarptautinis prekės ženklas. Taip pat yra užregistruotas Europos sąjungos intelektinės nuosavybės tarnyboje (ESINT), kaip Bendruomenės prekės ženklas.

Tai reiškia, kad nelicencijuotas šio prekės ženklo ar jo dalių naudojimas gali būti Bioenergy europe/EPC nuosavybės teisių pažeidimas. Bioegergy Europe/EPC turi teisę uždrausti neteisėtą ENplus® logotipo ir žymių naudojimą, taip pat reikalauti žalos atlyginimo. Be to mes galime skelbti informaciją apie sukčiavimą savo Juodajame sąraše.

ENplus® sertifikatas suteikia sertifikuotoms įmonėms teisę pakuoti savo granules į pakuotes ant kurių yra ENplus® logotipas.

Visi ENplus® pakuočių dizainai, prieš pradedant juos naudoti, turi būti patvirtinti Nacionalinio licencijuotojo - Asociacijos LITBIOMA.

Visa informacija, apie pakuotės dizainų patvirtinimą ir reikalavimus tam, yra pateikiama ENplus® Pakuotės dizaino gairėse ir ENplus® Vadove.

Granulių pakavimas į nepatvirtintas pakuotes yra draudžiamas. Bet koks šių reikalavimų netitikimas gali vesti prie sertifikuotos įmonės sertifikato sustabdymo ar nutraukimo, ar netgi iki įtraukimo į mūsų Juodajį sąrašą.

ENplus® žyma gali būti naudojama tik turint galiojančią licenciją. ENplus® Centrinis biuras ir Nacionaliniai licencijuotojai yra vienintelės įstaigos galinčios suteikti šį ženklą. Jis gali būti naudojamas reklaminėje medžiagoje ar ant pakuočių, bet tik siejant jį su ta sertifikuota įmone, kuriai jis buvo išduotas. Detali informacija pateikiama lentelėje* :

*atkreipkite dėmesį, kad čia pateikiami ID numeriai yra tik pavyzdžiai. Informacija apie leidžiamas spalvas ir jų kombinacijas yra pateikiama ENplus® Vadovo 3.0 (2 dalies), priede psl. 49-50.

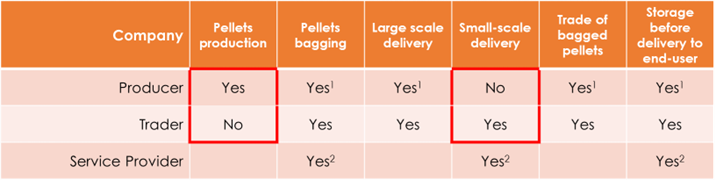

The purpose of the definition of the certification scope is to harmonise coverage of the “critical business activities” by the different ENplus® certifications.

The certification scope defines three basic types of companies: Producer, Trader and Service Provider. For Trader certification, three certification scopes are available: Trade of bulk pellets, Trader of bagged pellets and Trader of bulk pellets without physical contact.

All ENplus® documents include a chapter 2 named Normative references. This chapter lists the “external documents” that are referenced by the ENplus® documentation and have therefore become an integral part of the ENplus® requirements.

The normative documents can be presented in chapter 2 either as “dated” (e.g. ENplus® ST 1002:2022) or “undated” references (ENplus® ST 1002). For all undated references, the company shall use the latest version (including any amendments) of the particular document.

The ENplus® certification applies to three types of companies: Producers, Traders and Service Providers. The criteria used to decide whether a company is considered to be a Producer, a Trader or a Service Provider are primarily defined in ENplus® ST 1001, 4.1 for Producers, 4.2 for Traders and 4.3 for Service Provider:

1. A company that does not take ownership of the pellets is always considered to be a “Service Provider” (ENplus® ST 1001, 3.35). Only a company that offers services in bagging of pellets, small-scale delivery and/or storage of pellets in a facility from which the pellets are delivered to end-users can be considered to be a “Service Providers”. For all other services, a company is considered to be “external sub-contractor” (ENplus® ST 1001, 7.2.4.2).

2. Any company that has ownership of pellets shall be classified as either “Producer” or “Trader” (ENplus® ST 1001, 3.35).

3. Any company that is responsible for pellets production shall be considered to be “Producer” (ENplus® ST 1001, 3.33, 4.1).

4. Any company that is procuring pellets from other companies shall be considered to be “Trader”.

4.5. Any company that is responsible for small-scale delivery (with the pellets ownership) shall be considered to be “Trader” (ENplus® ST 1001, 3.39, 4.2).

5.6. A company that produces pellets and at the same time is responsible for the small-scale delivery shall be considered simultaneously Producer and Trader and shall hold two separate certificates, one for Producer activities and a second one for Trader’s activities (ENplus® ST 1001, 3.33, 3.39, 4.1,4.2).

1. A company that produces pellets and bagged pellets from its own production, or is responsible for large-scale delivery or for storage before the delivery to end-users from its own production, is considered to be Producer (only) and will only have “Producer certificate” (ENplus® ST 1001, 3.33, 4.1);

2. A company that produces pellets and at the same time trades pellets procured from other sources is considered to be “Producer” (for production and trade of its own pellets) and “Trader” (for trade of the pellets from other sources). It will need to have two certificates, one with the “Producer’s scope” and a second one with the “Trader’s scope”.

It should be noted that the requirements in Section 5 for Producers and in Section 6 for Traders that relate to the same activity (e.g. bagging of pellets) are identical. So, a company with both Producer and Trader certificates (scenario 2) does not need to implement different requirements for pellets from its own production and for pellets procured form other sources.

The purpose of the definition of the certification scope is to harmonise coverage of the “critical business activities” by the different ENplus® certifications.

The certification scope defines three basic types of companies: Producer, Trader and Service Provider. For Trader certification, three certification scopes are available: Trade of bulk pellets, Trader of bagged pellets and Trader of bulk pellets without physical contact.

“Critical business activities – always included in the certification scope” are those critical business activities that are “by default” included in the certification scope, regardless of whether or not they are, at the moment of inspection performed by the company. In case the company starts the critical business activity in between the inspections, no additional inspection is required.

Example: A trader with the certification scope “Trader of bulk pellets” starts a new activity of trade without physical contact after a regular inspection. Because the “trade without physical contact” is by default included in the certification scope, no additional inspection is required.

“Critical business activities – only included in the scope after the inspection” are those critical business activities that require an inspection before they can be included in the scope.

Example: A trader with the certification scope “Trader of bulk pellets” starts a new activity of a small-scale delivery after a regular inspection. Because the “small-scale delivery” can only be included in the scope after an inspection, the certification body shall conduct an inspection before it can add the “small-scale delivery” to the scope of certification.

Neither the definition of 3.28 nor requirements 4.4-4.7 (ENplus® ST 1001) require that the central office shall be a separate entity from the sites. Therefore, the central office, respectively “central function” can also be operated by one of the sites provided that it meets the requirements of ENplus® ST 1001, 4.4.

A single multisite company can only cover sites that are classified as either Producer or Trader or Service Provider.

If the sites belong to different categories (Producer, Trader, Service Provider) or some sites have activities of both, e.g. Trader and Producer, separate “multisite companies” have to be defined (with different set of sites). Each “multisite company” would receive a separate certificate for either Producer or Trader.

The term “multisite company” does not represent a legal entity but rather an organisation where “central function” and sites are defined.

A multisite company that covers “Producer sites” may be only established within one country, i.e. all the sites shall be located in one country.

A multisite company that covers “Traders sites” may be established across several countries, except Germany. This means that the sites located in Germany may only be organised under multisite company with a central office in Germany and the central office located in Germany can only include sites that are located in Germany (ENplus® ST 1001, chapter 4.6).

For multisite companies located outside Germany only:

The compliance with the eligibility criteria for the multisite company is evaluated by the certification body as a part of the application review. However, the eligibility shall also be approved by the ENplus® Scheme Management, i.e. ENplus® National Licensers in countries where they exist or by ENplus® International Management in countries without an ENplus® National Licensers (ENplus® ST 1001, 4.7). The company submits an application to the certification body and the certification body is responsible for contacting the relevant ENplus® Scheme Management and receiving the necessary permission (ENplus® ST 1001, 7.2.2).

When a multisite company covers sites located in more countries, the relevant ENplus® Scheme Management is the ENplus® Scheme Management of the country where the “central office” is located (ENplus® ST 1001, E.3.7). For example, for a multisite company (Trader certification) located in Austria with sites located in the Czech Republic, Slovakia and Hungary, the approval shall be received from the ENplus® National Licenser in Austria.

The multisite certification allows to include under one certificate several sites that can be a part of a single legal entity but can also be separate legal entities or independent legal entities (ENplus® ST 1003, 3.25).

In case of a multisite company, a single ENplus® ID is issued to the entire multisite company covering all the sites referenced in the certification scope (ENplus® ST 1003, 3.25).

Both options are possible.

The leading general requirement is that any bag design that is used for bagging ENplus® certified pellets shall be approved by the ENplus® Scheme Management (ENplus® ST 1001, 5.2.2.4, 6.2.2.3; ENplus® ST 1003, 7.2.3.1.1).

The company that owns the bag design, applies for the bag design approval and receives the approval from the ENplus® Scheme Management is called the ”bag design owner” (ENplus® ST 1001, 3.3). The ENplus® ID is always displayed at the bag design regardless of who bagged the pellets (ENplus® ST 1001, 3.3; (ENplus® ST 1003, 7.2.3.2.4).

1. Where the company bagging the pellets and uses its own bag design (i.e. it is the bag design owner), it shall ensure that the bag design has been approved by the ENplus® Scheme Management (ENplus® ST 1001, 5.2.2.4, 6.2.2.3, ENplus® ST 1003, 7.2.3.1.1).

2. Where the company bagging the pellets uses the bag design of another company, i.e. it is not the bag design owner, it shall receive a written permission from the bag design owner (ENplus® ST 1001, 5.2.2.4, 6.2.2.3, ENplus® ST 1003, 7.2.3.1.2). The content of this written permission shall include elements listed in ENplus® ST 1003, 7.2.3.1.2. The company receiving the permission should always check at the ENplus® website (www.enplus-pellets.eu) whether the bag design has been approved and who is the bag design owner.

Both.

The “bag design owner” is ultimately responsible that the bagged pellets comply with the bag design:

a) The company bagging the pellets shall ensure directly that the bagged pellets conform to information displayed on the bag design (ENplus® ST 1001, 5.2.2.4, 6.2.2.3).

b) When the bag design owner gave a permission to another company bagging the pellets to use the bag design, it shall ensure through an enforceable mechanism supported by a written contract that the bag design is used in compliance with the ENplus® requirements (ENplus® ST 1003, 7.2.3.1.1).

The term “enforceable mechanism” requires that the “permission” is a part of a written contract and that the compliance with the contract can be enforced by the bag design owner.

The company that is bagging (and is not the bag design owner) shall ensure that the bagged pellets conform to the information shown on the bag design by:

a) Permission / contract with the bag design owner (see above) and

b) Requirements of ENplus® ST 1001, 5.2.2.4, 6.2.2.3.

The term “information included on the applied bag design” (ENplus® ST 1001, 5.2.2.4, 6.2.2.3) covers all information on the applied bag design, such as the ENplus® quality class or pellets diameter but also fuel properties (ENplus® ST 1003, 7.2.3.2.12-15) and “additional information” such as species, geographical origin, forest certification scheme, etc. (ENplus® ST 1003, 7.2.3.2.16).

ENplus® ST 1001, 5.2.3.1 (for Producers) and 6.2.3.1 (for Traders) include a requirement applying to all “outgoing pellets”.

However, it also includes an exemption in a situation where all three conditions have been met (ENplus® ST 1001, 5.2.3.1, 6.2.3.1):

a) The pellets are not directly delivered to an end-user;

b) The higher amount fines is specified in the contract between the company and its customer; and

c) It is ensured that subsequent separation of fines before the delivery to the end-user will take place.

The standard (ENplus® ST 1001, 5.2.3.2, 6.2.3.2) does not define any specific technology or methodology for measuring the temperature. Instead, it defines the objective that the “outgoing pellets shall not exceed 40 °C”. And this objective applies to the whole time period when the pellets are loaded.

It is up to the certification body to evaluate the technology and methodology used, taking into account the geographical location of the loading site, seasonal or daily changes in temperature, etc.

The standard requires that the temperature shall be measured at least once per day during the loading process (ENplus® ST 1001, 5.2.4.1, 6.2.4.1). This means that no measurement is required during the days without loading.

The standard (ENplus® ST 1001, 5.2.3.2, 6.2.3.2) requires that pellets that exceed 40°C shall not be delivered to the end-user.

Concerning the delivery to another trader (B2B), the company can deliver the pellets with temperature higher than 40 °C under the condition that the delivery documentation:

a) Informs the customer about the increased temperature and

b) Includes information about the risks associated with the higher temperature.

The information about the pellets temperature exceeding 40°C (see bullet point a) shall be included in the delivery documentation (ENplus® ST 1001, 5.2.5.1, 6.2.5.1)

In general, the risks associated with higher temperature of wood pellets are “off-gassing”, i.e. emitting Co and CO2 by pellets decomposition process and “self-heating” and self-ignition of the pellets in the storage.

During the revision, some new parameters have been added to the ENplus® requirements: share of pellets with a length < 10 mm, particle density and coarse fines (3,15 mm ≤ FP < 5,6 mm).

Those new parameters do not include a threshold value as more data needs to be collected to set up the threshold value. Therefore, the standard requires those parameters to be tested and reported, respectively within the testing reports.

The outcomes may be used by the company for their own quality control and will also be used by the ENplus® scheme management for the future development of the scheme.

Measuring the raw material quality is not a specific requirement of the scheme, even though it is recommended. The only "mandatory" information is the origin, according to ISO classification (ENplus® ST 1001, 5.1.2.1, Annex A.2), and a visual evaluation of the quality and the contamination of the raw material.

The company that is responsible for loading the pellets, i.e. operating the loading site is responsible for checking the cleanliness of the loaded transport vehicles. The company shall keep records, i.e. as a part of the delivery documentation that the cleanliness of the transport vehicle has been checked (ENplus® ST 1001, 5.2.3.5, 6.2.3.11).

The standard provides an exemption of fully automated loading sites without company’s personnel where the cleanliness of each loaded transport vehicle cannot be checked. In this case, the company shall include a clear statement that the transport vehicle has not been checked for contamination.

The company that is responsible for loading the bulk pellets, i.e. operating the loading site is responsible for checking the cleanliness of the loaded transport vehicles. The company shall keep records, i.e. as a part of the delivery documentation that the cleanliness of the transport vehicle has been checked (ENplus® ST 1001, 5.2.3.5, 5.2.4.3, 6.2.3.11, 6.2.4.3).

Although the big bag, by definition is considered to be “bulk pellets” this requirement does not apply to the transport of big bags as the big bags themselves ensure that the pellets cannot be contaminated by the transport vehicle.

The self-monitoring for fines is required in all situations (ENplus® ST 1001:2022, 5.2.4.1, 6.2.4.1) as the self-monitoring of fines is focused on the proper performance of the sieving device.

The separation of fines is not required, under certain conditions, when the pellets are not directly delivered to end-users (ENplus® ST 1001:2022, 5.2.3.1, 6.2.4.1). In those situations, the company is also not required to conduct self-monitoring of fines (ENplus® ST 1001:2022, 5.2.4.1, 6.2.4.1).

No. The self-monitoring is only required for fines ≤ 3,15 mm.

The course fines (3,15 mm ≤ FP < 5,6 mm) have been added to the pellet’s parameters in the recent revision (2022) without threshold value (ENplus® ST 1001, Annex 1.1). The purpose was, at this stage to monitor the amount of the course fines.

No. The self-monitoring is only required for amount of fines (≤ 3,15 mm), temperature, and cleanliness of transport vehicles (ENplus® ST 1001:2022, 6.2.4.1, 6.2.4.3).

Chapter 6.1.1 requires that the trader with bagging activities is responsible for conformity of mechanical durability and amount of fines. This means that the certification body shall perform a testing for mechanical durability.

Yes.

The standard includes separate self-monitorings for production and bagging process (ENplus® ST 1001, 5.2.4.1).

However, the company is also allowed to only collect sample from one sampling point after the bagging process provided that there is no intermediate storage between the production and bagging (ENplus® ST 1001, 5.2.4.3).

Yes.

Where the results of the testing conducted by the certification body shows that the pellets are not conforming to a threshold value of any of the parameters or are close to the threshold value (ENplus® ST 1001, Annex A.1), the company shall also implement self-monitoring for that particular parameter(s).

Where the pellets do not conform to the threshold value, the additional self-monitoring is defined as a part of the corrective actions for major non-conformity (ENplus® ST 1002:2022, 7.3.4).

Where the tested pellets are close to the threshold values, the additional self-monitoring is defined as a preventive action to address an observation and prevent possible non-conformity (ENplus® ST 1002:2022, 7.3.4).

The additional self-monitoring can be lifted after the subsequent testing by the certification body that confirms improvement of the pellets performance.

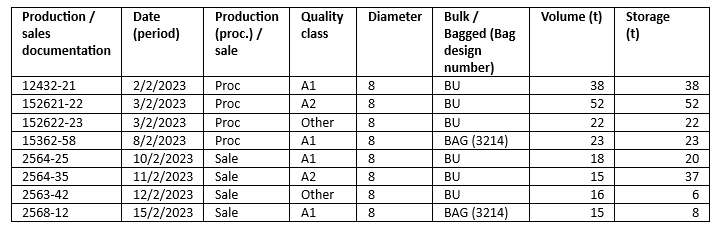

The objective of the mass balance account (MBA) is to provide information about all transactions of ENplus® certified pellets and other pellets. The input transactions are either outcomes of the production process (Producers) or procurement of pellets (Traders). The output transactions are sales of pellets. The difference between the sale and procurement (production) is the amount of pellets in storage.

Individual input transactions shall be supported by production documentation (Producer) or procurement documentation (Trader). Individual output transactions shall be supported by sales documentation.

For individual transactions, the following shall be included in the MBA: ENplus® quality class, diameters, bag design, bulk/bagged pellets, date of the transaction/period, volume (ENplus® ST 1001, 5.2.5.3, 6.2.5.4).

Example of MBA:

The mass balance account (MBA) shall include input transactions for all pellets. In case of production, the input transaction is production of pellets, respectively volume of pellets leaving the production.

Contrary to procurement of pellets, there is no verifiable documentation of an external organisation (e.g. an invoice) and the production volume shall therefore be documented by internal production documentation. Such documentation shall be verifiable and shall include all information required in the MBA (ENplus® ST 1001, 5.2.5.3).

The “internal production documentation” shall provide transactions for specific date or for specific time period. The time period shall be defined based on internal production circumstances, inventory procedures, etc.

The standard does not explicitly define whether “internal transactions” to and from the “intermediary storage” shall be included in the MBA. However, the standard requires that the MBA shall include information on pellets in storage (ENplus® ST 1001, 5.2.5.3d, 6.2.5.4d) and shall allow verification that the volume of outgoing ENplus® pellets does not exceed volume of procured / produced pellets.

Scenario A: The intermediary storage, when all pellets are used in subsequent processing (e.g. bagging) does not need to be included in the MBA. The intermediary storage has no impact on the verification of whether the volume of sold pellets exceeds the volume of produced / procured pellets or not.

Example: Company produces pellets and stores them before bagging. All pellets from that “intermediary storage” are delivered to the bagging process and are not used for sales.

Scenario B: The intermediary storage shall be included in the MBA when the part of the stored pellets continues to subsequent processing and other part is delivered to customers. The intermediary storage has impact on the verification of whether the volume of sold pellets exceeds the volume of produced / procured pellets or not.

The delivery of pellets to the intermediary storage is considered to be an input transaction and the outgoing pellets from the intermediary storage is considered to be outgoing transaction.

Example: Company produces pellets and stores them before bagging. Some volume from the stored pellets is sold to customers and some are used for bagging purposes. The company shall include the internal transactions to and from the storage in the MBA. The pellets leaving the production to the storage are “input transaction” (internal production documentation) and pellets leaving the pellets to the bagging process are “output transaction” (internal delivery/inventory documentation). For the bagging process, the pellets from the intermediary storage as considered to be “input transaction” (internal delivery/inventory documentation) and sales of bagged pellets are considered outgoing transaction (sales documentation).

The standard does not define any software or specific information system that shall support the mass balance account (MBA). The company can use existing information system provided that it can deliver information on all the transactions (incoming and outgoing) and includes all information required by the standard (ENplus® ST 1001:2022, 5.2.5.3, 6.2.5.4).

When the company uses the internal product codes that cover specific properties of pellets (e.g. ENplus® quality class, diameter, bulk/bagged, the bag design approval number), the company can keep the mass balance account for specific “product codes”, as long as all the information covered by the specific product code can be retrieved indirectly.

The mass balance account shall be kept for all produced/traded pellets, ENplus® certified pellets as well as other pellets (ENplus® ST 1001, 5.2.5.3a, 6.2.5.4a).

The trader is only allowed to accept procured pellets as ENplus® certified if the supplier holds a valid ENplus® certification (ENplus® ST 1001, 6.2.1.3).

In order to demonstrate that the supplier is ENplus® certified, the company should:

a) Verify that the delivery documentation, includes supplier’s ENplus® certification seal or ENplus® ID (ENplus® ST 1001, 5.2.5.1, 6.2.5.1); and

b) Verify the validity of the certification at the ENplus® official website (ENplus® ST 1001, 6.2.1.3).

The company should also request the supplier to provide a copy of the ENplus® certificate.

Yes.

A company can either use the sampling and testing methods described in ISO 17225-2 or develop its own specific methodology (this also applies to testing equipment).

Where the company’s own methodology deviates from ISO 17225-2, it shall validate its efficiency by a comparative measurement and get an approval by its ENplus® certification body (ENplus® ST 1001:2022, 7.3.1.2).

The approval by ENplus® certification body is also required when the company uses other sampling point than from falling material (or sampling of bagged pellets).

The trader is only allowed to accept procured pellets as ENplus® certified if the supplier holds valid ENplus® certification (ENplus® ST 1001, 6.2.1.3).

Where the company regularly procures pellets from one or more suppliers, the company shall:

a) Verify the certificate validity at the ENplus®official website at the time of the first delivery; and

b) Verify the certificate validity at the ENplus® official website in regular time intervals.

The standard does not prescribe a technology that can be used for small scale delivery of pellets. Instead, it requires that the technology prevents a significant increase of fines and that the technology is approved by the ENplus® International Management for the use in countries outside Germany and by DEPI for the use in Germany (ENplus® ST 1001, 6.2.3.4).

There are two options that the company can follow:

a) The technology that the company is using is included in the list of approved technologies kept by ENplus® International Management and DEPI;

The list is presented at the ENplus® official website (www.enplus-pellets.org) concerning the delivery outside Germany. For deliveries to end-users in Germany, the company shall contact DEPI directly.

b) When the technology is not included in the list referred above, company shall apply to ENplus® International Management or DEPI for approval of the specific technology and submit both the relevant testing protocol and testing results.

The application for the approval of the technology can also be submitted by the technology manufacturer, an industry association or other entity. When the approval is given, the technology will be included in the list of approved technologies referred under bullet point a.

The company shall always check the country of delivery and whether the technology it uses for small-scale delivery has been approved for the particular country.

a) For Germany, the technologies are always approved by DEPI and the approval is only valid for deliveries in Germany.

b) Outside Germany, the technologies are approved by the ENplus® International Management (European Pellets Council) and each approved technology also includes a geographical scope of the approval. Some technologies are approved for all countries (except Germany, see bullet point a), others can be approved for specific region or specific countries.

For the list of approved technologies, visit the ENplus® official website (www.enplus-pellets.org) concerning the delivery outside Germany. For deliveries to end-users in Germany, the company shall contact DEPI directly.

The company is required to only use for the small-scale delivery the technologies that have been approved by ENplus® International Management (for deliveries outside Germany) and by DEPI (for deliveries in Germany) (ENplus® ST 1001, 6.2.3.4).

The technologies are approved for specific geographical scope (ENplus® ST 1001, 6.2.3.4).

Therefore, the company shall keep a list of all transport vehicles for small-scale delivery that includes for each transport vehicle, at least (ENplus® ST 1001, 6.2.3.4):

a) Clear identification of the transport vehicle;

b) Technology used;

c) Information on whether the technology has been approved or not and for which countries;

d) Countries where the transport vehicle is used.

Concerning the technology used, the description of the technology should, at least include a detail that allows to compare the technology with the list of approved technologies kept by the ENplus® International Management and DEPI.

The Data Sheet – Transport Vehicles for small-scale delivery, available here has been created for fulfilling this requirement.

Yes.

The new standard ENplus® ST 1001 allows to include in the certification scope vending machines that are automated self-service machines, usually available 24/7, allowing end-users to obtain bulk pellets.

The new standard ENplus® ST 1001 (6.2.3.13) defines basic parameters of the vending machines that ensure:

a) Amount of fines not exceeding 1 % of the volume;

b) Temperature not exceeding 40°C

c) The end-user to receive delivery documentation with the elements required for regular sale of pellets.

As the sale of bulk pellets through vending machines is a new concept and the technologies are in early stage of development, the standard (ENplus® ST 1001, 6.2.3.13d) requires that the technology shall be approved by ENplus® International Management (for all countries except Germany).

The application for the approval of the vending machine technology is submitted to ENplus® International Management through the relevant certification body of the company. This shall include manufacturer, description of the technology for separation of fines, temperature monitoring, printing of delivery documentation and operating manual. The Data Sheet – Vending Machine has been created for fulling this requirement.

The new standard ENplus® ST 1001 (5.2.5.1, 6.2.5.1) does not define a specific type of the delivery documentation communicated for the outgoing pellets that shall be used to include mandatory information.

The definition of the term “delivery documentation” states that “A delivery note, a bill of loading or an invoice, used individually or in combination, are examples of delivery documentation” ENplus® ST 1001 (3.11).

However, it should be clearly communicated to the customer and customer should be aware of what type of the delivery documentation bears mandatory requirements required by the ENplus® standard.

The trader with small-scale delivery shall include in the delivery documentation “obvious defects” of the end-user storage room. Those defects relate to the ENplus® Storage Guidelines applicable in the respective country of delivery.

The ENplus® Storage Guidelines are developed by:

a) DEPI for Germany,

b) ENplus® National Licensers for their particular countries and

c) ENplus® International Management for all countries without ENplus® National Licensers, except Germany.

The ENplus® Storage Guidelines published by the ENplus® International Management as ENplus® GD 3001 defines in chapter Scope which sections of the document are relevant to the check-up by the trader during the delivery.

The objective of the requirement is to ensure, at the time of the delivery, information that can be useful and important in an apparent investigation of complaints or nonconforming products.

Yes.

The standard (ENplus® ST 1001, 7.2.1.3) includes requirements for infrastructure and also makes references to storage of pellets, and protection of pellets from moisture and contaminations.

Therefore, the storage of pellets (both bulk and bagged pellets) shall be included in the scope of certification.

The standard requires that the reference samples shall be identifiable (ENplus® ST 1001, 7.3.3.4). The details needed are: date, production or loading site, and ENplus® quality class. It is acceptable to use the delivery note number as long as it is possible to find this information.

The new standard ENplus® ST 1001 (5.2.5.1, 6.2.5.1) requires that the delivery documentation for bagged pellets shall include the bag design approval number. The latest edition of the ENplus® requirements (ENplus® ST 1001, ENplus® ST 1003, ENplus® PD 2003) defines a system in which approved bag design is identifiable through a unique “bag design approval number”. The number is issued by the ENplus® scheme management to the “bag design owner” as a part of the bag design approval.

When the company uses an internal article number (a product code) that is specific to bag pellets with specific bag design, the company can include in the delivery documentation the “internal article number” instead of “the bag design approval number”. The objective of this optional implementation is to always allow clear identification of the bag design in the delivery documentation.

No.

The new standard ENplus® ST 1001 (5.2.5.1, 6.2.5.1) requires that the delivery documentation for bagged pellets shall include the bag design approval number. Therefore, it shall be there regardless of whether the number is displayed on the bag or not.

If the “bag design owner” decides to include the bag design number on the bag design, this would be considered as “additional information” as per ENplus® ST 1003, 7.2.3.2.16.

The company bagging pellets shall include in the bag design a serial number (ENplus® ST 1001, 7.3.2.4; ENplus® ST 1003, 7.2.3.2.11).

The standard does not prescribe any specific format of the serial number, it can be a numerical or alfa-numerical code, a bar code or even a QR code. The standard does not require that a customer or an end-user shall be able to “decode” the serial number. However, the serial number shall allow the company to identify:

a) The entity responsible for bagging the pellets, including a bagging site,

b) Date and site of the bagging.

The serial number shall also be printed directly on the bag.

The implementation of the serial number requirement has obtained an extended transition period until 1 January 2025.

The standard does not prescribe any specific format of the serial number, it can be a numerical or alfa-numerical code. However, the serial number shall allow identification of:

a) The entity responsible for bagging the pellets;

b) Date and site of the bagging.

The bag design owner is the ENplus® certified company that submitted an application for the approval of the bag design and received the approval. It is expected that the ENplus® is an intellectual property of the bag design owner (ENplus® ST 1003, 3.2, 7.2.3.1.1).

With the “approval of the bag design” the bag design owner is the entity that is allowed to use the ENplus® bag design and has also full and ultimate responsibility for the proper use of the ENplus® bag design in conformity with the ENplus® requirements (ENplus® ST 1003, 3.2, 7.2.3.1.1).

The bag design owner is allowed to give a written permission to another ENplus® certified company that is bagging the pellets for the bag design owner (ENplus® ST 1003:2022, 7.2.3.1.2).

The permission shall have a form of an enforceable written contract that meets the conditions of (ENplus® ST 1003, 7.2.3.1.2) and ensures the bag design use is in compliance with the ENplus® requirements.

The ENplus® bag design shall always include clear identification of the bag design owner, its name, address, website and email address.

The bag design owner can also include in the bag design another company. However, it shall be clear and unambiguous from the bag design by the “font size” and by “introduction” of the company, e.g. “distributor: name, address” who has the overall responsibility for the pellets quality and the use of the ENplus® bag design (ENplus® ST 1003:2022, 7.2.3.1.2).

No.

The standard requires that the serial number shall be a part of the bag design (ENplus® ST 1003:2022, 7.2.3.2.11).

No.

The standard requires that all information included in the bag design shall be printed on the bag directly (ENplus® ST 1003:2022, 7.2.3.1.3). This ensures that the information cannot be changed or removed during the next stages of the trading process.

The company is allowed to display on the bag design additional information about the pellets properties that can be presented as either (ENplus® ST 1003, 7.2.3.2.12):

a) using the threshold values of the ENplus® scheme (ENplus® ST 1001, Annex 1.1); or

b) stricter threshold values.

The option of using the “stricter values” as well as the value itself is selected by the company (bag design owner) themselves. Therefore, the company has also full responsibility for the pellets conformity for those values.

1. At the time of the bag design approval, the company shall provide the ENplus® scheme management with laboratory analysis confirming the pellets conformity. The laboratory analysis shall be conducted by ENplus® testing body as a part of the certification process (ENplus® ST 1003, 7.2.3.2.15a). The conformity is checked by the ENplus® scheme management as a part of the bag design approval process.

2. At the time of bagging, the company shall ensure that the bagged pellets conform to the “stricter values”. This shall be confirmed by the latest test results conducted by the ENplus® testing body as a part of the certification process. The conformity is checked by the ENplus® certification body as a part of the certification process (ENplus® ST 1003, 7.2.3.2.15c).

3. When the pellets are procured from another ENplus® certified company, the bag design owner and/or company responsible for bagging shall request results of the pellets testing from the pellets producer (ENplus® ST 1003, 7.2.3.2.15);

4. When the bagged pellets originate in several plants, all testing results shall conform to the stricter values (ENplus® ST 1003, 7.2.3.2.15b).

5. When the bagging is performed by another ENplus® certified company based on permission from the bag design owner (ENplus® ST 1003, 7.2.3.1.2), both the bag design owner (ENplus® ST 1003, 7.2.3.1.2, 7.2.3.2.15e) as well as the company performing the bagging (ENplus® ST 1001, 5.2.2.4, 6.2.2.3).

The company is allowed to display in the bag design additional information about the pellets that is not covered by the ENplus® scheme. This also includes labels and claims for other certification schemes (ENplus® ST 1003, 7.2.3.2.16). An example can be a forest certification scheme (FSC or PEFC).

The bag design owner is responsible that the claim is accurate, verifiable and non-misleading (ENplus® ST 1003, 7.2.3.2.16) and also ensures that the pellets are conforming to the presented claims (ENplus® ST 1003, 7.2.3.2.16; ENplus® ST 1001, 5.2.2.4, 6.2.2.3). This also applies to the company bagging the pellets when the bag design is used based on the permission of the bag design owner (ENplus® ST 1003, 7.2.3.1.2).

In case of using the claims of another certification scheme (e.g. PEFC or FSC), the presented claims and labels shall:

a) Comply with the requirements of the particular scheme;

b) The company shall hold a valid certificate that is recognised by the particular certification scheme.

The valid certificate recognised by the referenced certification scheme (e.g. PEFC or FSC) is then used as the “presumption of conformity” and the pellets compliance with the claim does not need to verified by the ENplus® scheme management and ENplus® certification body.

However, the ENplus® scheme management shall verify, as a part of the bag design approval that the used label and the wording of the claim conform to the requirements of the particular scheme.

The company is allowed to display in the bag design additional information about the pellets that is not covered by the ENplus® scheme and ENplus® certification, for example wood species, country of origin, forest certification scheme, etc.

For all cases when the company contracts an external company to conduct any activity that is regulated by the ENplus® requirements. In principle, there are two types of sub-contracting:

a) Sub-contracting of bagging of pellets, small-scale delivery and storage of bulk pellets in a facility from which they are delivered to end-users (ENplus® ST 1001, 7.2.4.1);

b) Any other activity regulated by the standard (ENplus® ST 1001, 7.2.4.2).

The activities under bullet point a are considered to have higher risk concerning the pellets quality and any sub-contractor shall either hold valid ENplus® certification for the performed qualification (Producer, Trader or Service Provider) or shall be considered as “uncertified service provider” and considered as a site of the multisite company.

Yes.

Bagging of pellets (together with small-scale delivery and storage of pellets before delivery to an end-user) is regulated by ENplus® ST 1001, 7.2.4.1.

The company can use another certified Trader (ENplus® ST 1001, 7.2.4.1b) as a sub-contractor for bagging pellets (where the sub-contractor does not take ownership of pellets). The Trader shall have valid ENplus® certification and the scope of the certification shall cover bagging of pellets.

In this case, the company can consider the sub-contracted activities as complying with the ENplus® requirements.

The same rules also apply for small-scale delivery and storage of pellets before delivery to an end-user.

A company that offers bagging of pellets, small-scale delivery and storage of pellets before delivery to an end-user without taking ownership of pellets is considered to be a “service provider”.

The service provider can either:

a) Have its own ENplus® ST 1001 certification; or

b) Be considered as a site of a company for which it is performing the service (multisite company).

Having its own ENplus® certification (bullet point a) has an advantage for the service provider – it allows the service provider to deliver the service to more companies because the company is inspected only once as a part of its own ENplus® certification.

If the service provider does not hold its own ENplus® certification, it is considered to be a site of each company it is delivering the service to and shall be included in the inspection of every company.

A sub-contractor that is for a company performing bagging of pellets (without taking ownership of the pellets) is considered as “service provider” (ENplus® ST 1001, 7.2.4.1c.)

In this case, the service provider shall be fully under control of the company and also shall be inspected by the certification body as an integral part of the company’s certification.

Therefore, the “uncertified service provider” is considered as a site of the company and the company together with the service provider (other sites is considered as “multisite company” and shall follow eligibility requirements for the multisite company (ENplus® ST 1001, 4.4-4.7) in addition to the general requirements for sub-contracting (ENplus® ST 1001, 7.2.4).

The same rules also apply for small-scale delivery and storage of pellets before delivery to an end-user.

The company shall have procedures for investigation and resolution of complaints relating to the quality of pellets, respectively conformity of the ENplus® certified pellets and ENplus® certified company with the ENplus® requirements.

Complaints from stakeholders that relate to other issues (e.g. financial, sustainability, product design, or uncertified pellets) are not regulated by the ENplus® standards and are outside the scope of the ENplus® certification.

The company is required to receive a complaint, investigate it, make a decision and inform the complainant in writing about the outcome of the investigation (ENplus® ST 1001:2022, 7.3.4.5).

The standard does not predefine the outcomes of the complaints investigation and the company can reject the complaint as:

a) Not related to the scope of the ENplus® certification;

b) Not related to the company’s activities;

c) Not justifiable in regard to the compliance with the ENplus® requirements.

When the company rejects the complaint as not related to its activities, scope of the ENplus® certification or when the complainant is not satisfied with the outcomes of the investigation, the company shall inform the complainant about the possibility to re-submit the complaint to the ENplus® scheme management.

The company does not need to engage the same testing body that was involved in the ENplus® certification process. The company can contact any testing body that is accredited for the tests to be performed. The accreditation shall be valid and issued by a national accreditation body that is a member of the EA (European cooperation for Accreditation) or ILAC (International laboratory Accreditation Cooperation).

The use of an external, accredited testing body is not required when the investigation of complaints concerns the following pellets parameters: fines content, moisture, mechanical durability and bulk density.

In this case the testing can be performed by the company itself.

Trader of bagged pellets (that is not the “bag design owner”) is not required to have the ENplus® certification (ENplus® ST 1001, 4.2, Annex B). However, the entity trading with ENplus® certified pellets can’t mix these pellets with other pellets and their quality should not deteriorate (significantly) during the trading process.

Therefore, the trader of bagged pellets (that is not the bag design owner) can use the ENplus® Trademark under two alternative options for both on-product as well as off-product use:

a) The trader can apply for an “approval for the use of the ENplus® Trademark” from the ENplus® scheme management (ENplus® ST 1003, 7.1.2);

b) The trader can receive a written permission from an ENplus® certified company (ENplus® ST 1003, 7.1.3).

The main difference between those two options is that the “approval” from the ENplus® scheme management applies to all traded ENplus® certified pellets while the permission from the ENplus® certified company applies only to the ENplus® certified pellets of that particular certified company.

Entities outside the supply chain having interest in promoting wood pellets can use the ENplus® Trademark only for off-product purposes (ENplus® ST 1003, 5).

The category of “other users” (ENplus® ST 1003, 6d) represents a broad range of stakeholders including ENplus® scheme governing bodies, conformity assessment bodies, pellets end-users, boiler and stove manufacturers, research and educational institutions, etc.

Other users do not need to obtain an ENplus® trademark license and a very simple rule requires them to only use the ENplus® Trademark in a way that is not misleading or intentionally harming the ENplus® scheme (ENplus® ST 1003, 5.6).

An ENplus® certified company is allowed to give a permission for the use of the ENplus® Trademark to its business partners without ENplus® certification.

However, this permission can be given only to three types of companies (ENplus® ST 1003, 7.1.3):

a) an entity working as an intermediary trader that does not take ownership of the traded bulk pellets (a broker);

b) an entity that trades bulk pellets without physical contact;

c) a trader of bagged pellets.

This permission shall be made in writing and shall cover the restrictions specified in ENplus® ST 1003, 7.1.4, in particular it can be used only in connection to products supplied by the ENplus® certified company issuing the permission and with its ENplus® ID number.

The ENplus® certified company shall report immediately the issued permission to the certification body and to the ENplus® scheme management (ENplus® ST 1003, 7.1.3).

The ENplus® Trademarks and labels (consisting of the ENplus® Trademark) can only be used in colours that are specified in Annex A. This covers, three main colours patterns: official colour combination (orange and grey), monochrome black and white and monochrome coloured.

Etiam magna arcu, ullamcorper ut pulvinar et, ornare sit amet ligula. Aliquam vitae bibendum lorem. Cras id dui lectus.

63739 street lorem ipsum City, Country

+12 (0) 345 678 9

info@company.com

asdasdfasdf